ProductsBearingsCustom Bearings

Custom Bearings

Our vertically-integrated engineering and manufacturing services provide a one-stop shop for custom bearings.

- Large selection of materials, including superalloys.

- Produced with fast, efficient metal hybrid manufacturing.

- Support for one-off proof of concept or a short-run production, with pathway to scale.

- ISO 9001 and AS9100 third-party certified.

- CMMC Level 2 and DFARS 252.204-7012 compliant.

- Designed and manufactured in the USA.

Sample Specifications

Specifications listed as typical ranges.

Bearing Type |

Inner Dimension (in) |

Outer Dimension (in) |

Width (in) |

Static Load Capacity (lbf) |

Operational Speeds (RPM) |

Operating Temperature (F) |

|---|---|---|---|---|---|---|

Single Row Angular |

0.500 – 6.375 |

2.000 – 11.875 |

0.250 – 1.125 |

1,500 – 10,000 |

200+ |

200 – 500 |

Double Row Angular |

0.500 – 6.375 |

2.000 – 11.875 |

0.750 – 2.750 |

5,000 – 15,000 |

200+ |

200 – 500 |

Needle Roller |

0.250 – 6.375 |

1.000 – 11.875 |

0.500 – 3.875 |

15,000 – 50,000 |

200+ |

200 – 500 |

Cylindrical Roller |

0.250 – 6.375 |

1.000 – 11.875 |

0.500 – 3.875 |

15,000 – 50,000 |

200+ |

200 – 500 |

Double Row Deep Groove |

0.500 – 6.375 |

2.000 – 11.875 |

0.750 – 2.750 |

5,000 – 15,000 |

200+ |

200 – 500 |

Specifications listed as typical ranges.

Bearing Type |

Inner Dimension (in) |

Outer Dimension (in) |

Width (in) |

Static Load Capacity (lbf) |

Operational Speeds (RPM) |

Operating Temperature (F) |

|---|---|---|---|---|---|---|

Single Row Angular |

0.500 – 6.375 |

2.000 – 11.875 |

0.250 – 1.125 |

1,500 – 10,000 |

200+ |

200 – 500 |

Double Row Angular |

0.500 – 6.375 |

2.000 – 11.875 |

0.750 – 2.750 |

5,000 – 15,000 |

200+ |

200 – 500 |

Needle Roller |

0.250 – 6.375 |

1.000 – 11.875 |

0.500 – 3.875 |

15,000 – 50,000 |

200+ |

200 – 500 |

Cylindrical Roller |

0.250 – 6.375 |

1.000 – 11.875 |

0.500 – 3.875 |

15,000 – 50,000 |

200+ |

200 – 500 |

Double Row Deep Groove |

0.500 – 6.375 |

2.000 – 11.875 |

0.750 – 2.750 |

5,000 – 15,000 |

200+ |

200 – 500 |

Specifications listed as typical ranges.

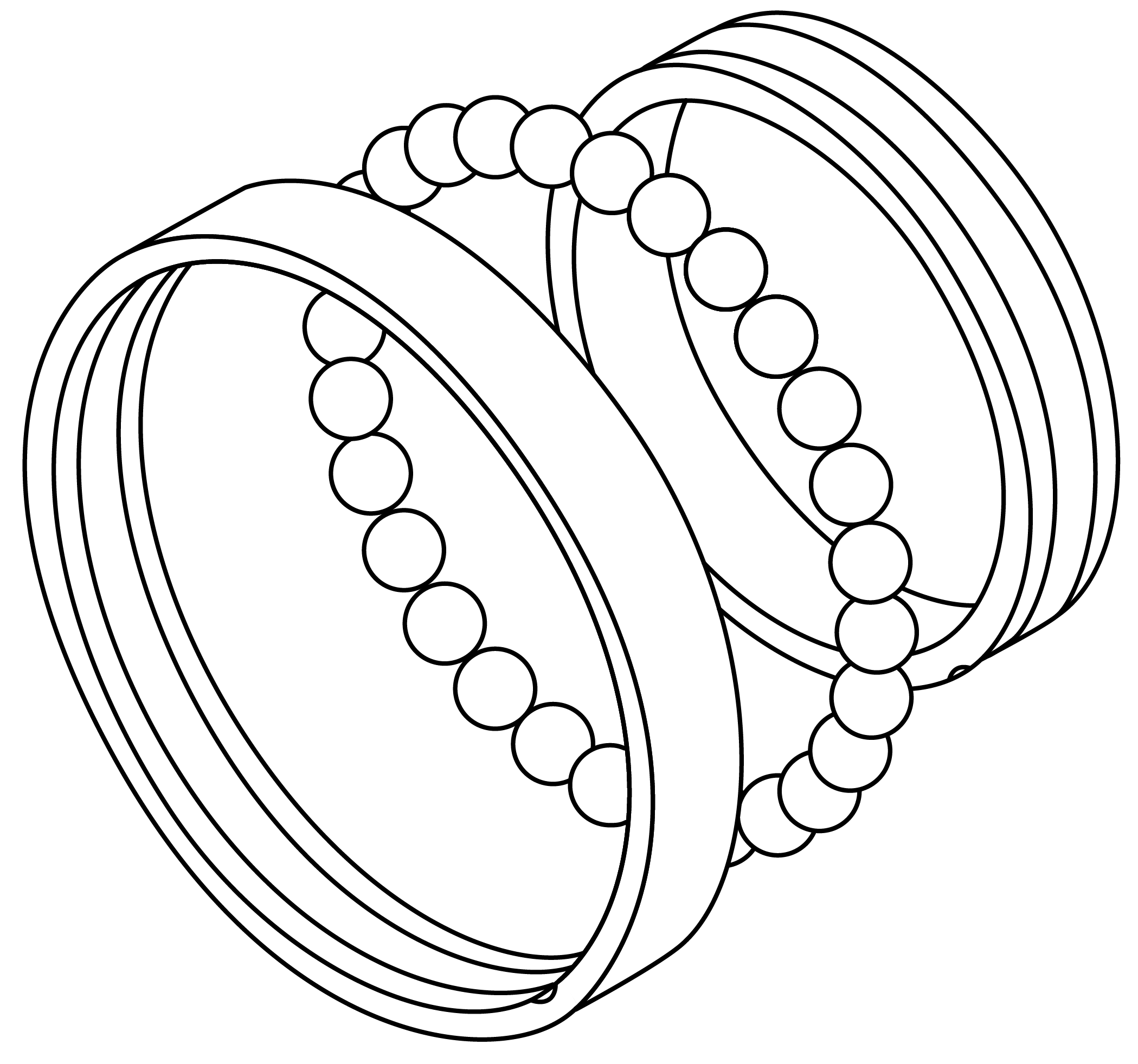

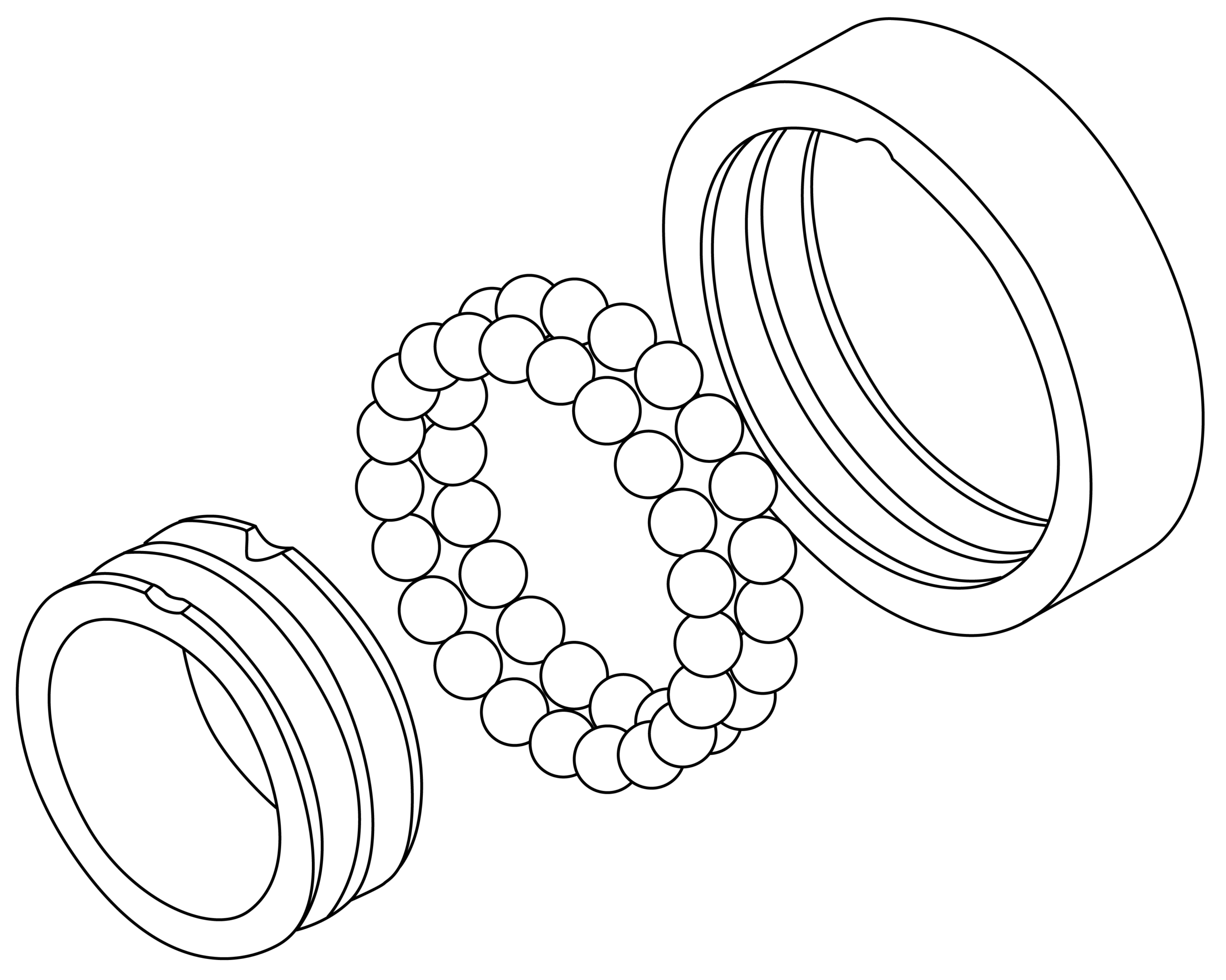

Single Row Angular Contact Ball Bearing

Single Row Angular Contact Ball Bearing

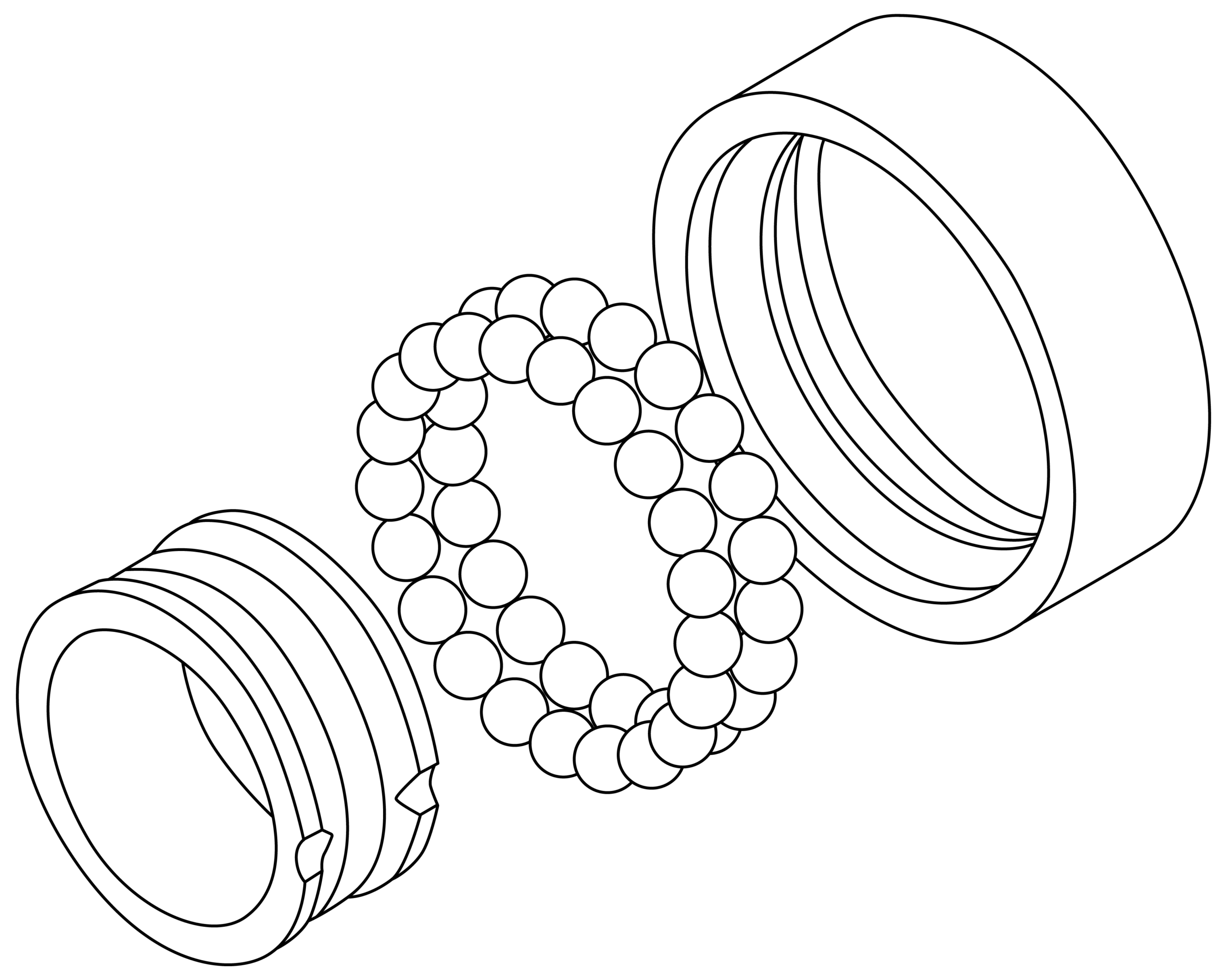

Single Row Needle Roller Bearing

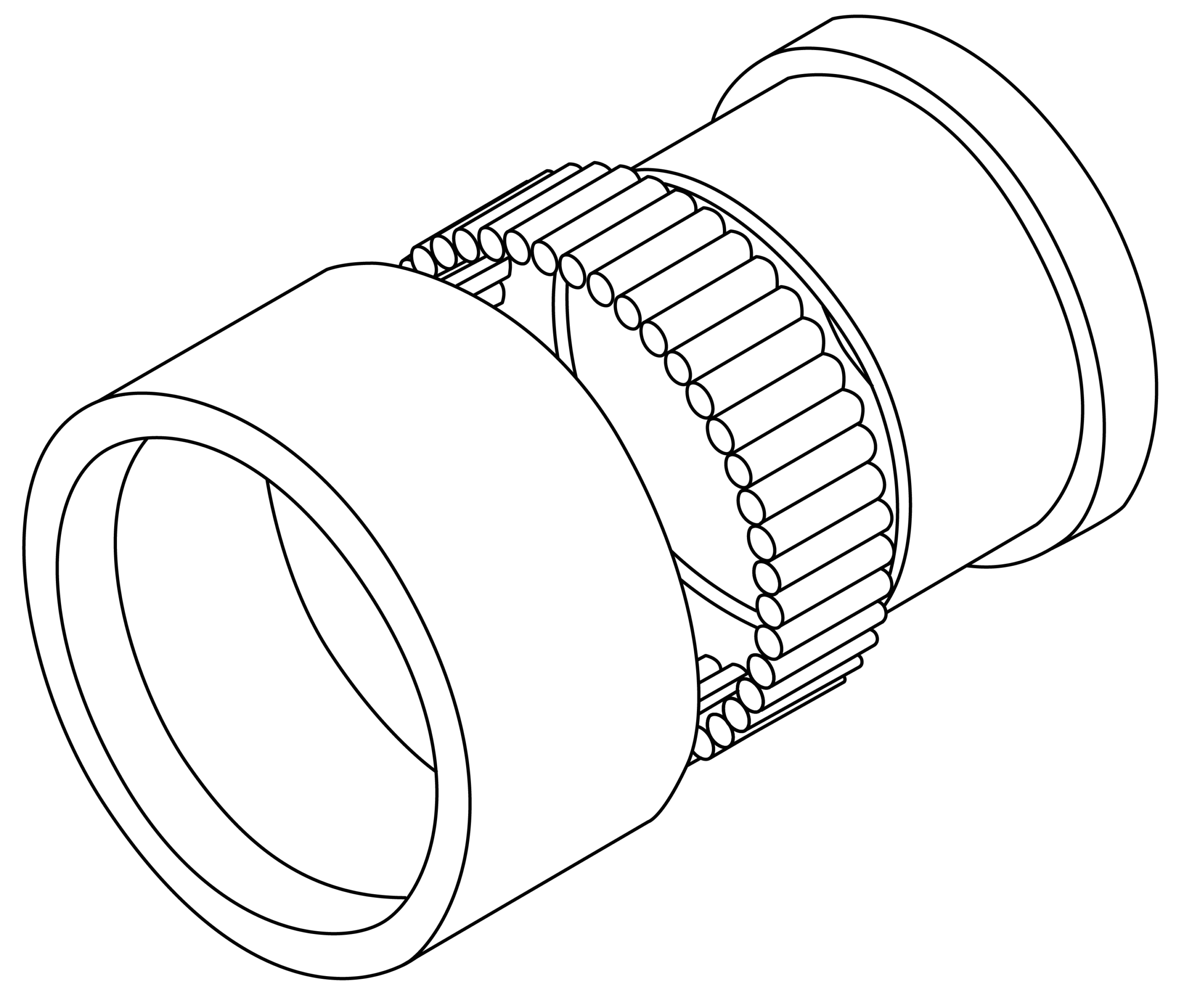

Single Row Cylindrical Roller Bearing

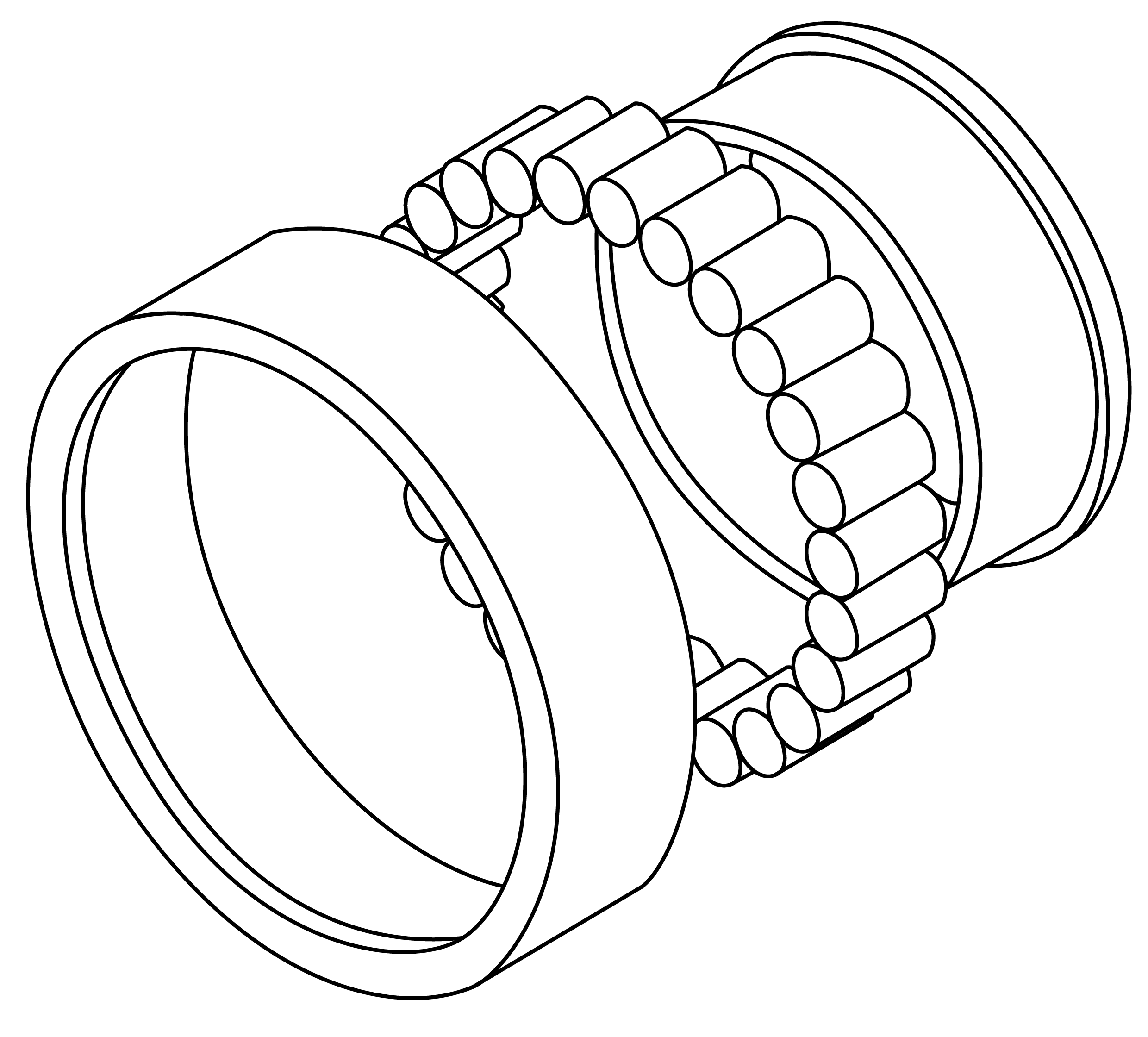

Double Row Deep Groove Ball Bearing

Materials

We make bearings in a wide variety of materials, and can help you select the best ones for your requirements.

High-performance options include:

Looking for something else?

Looking for something else?

Working with wire feedstock means our material options are pretty extensive. We can also produce multi-alloy components, which are ideal for bearings that might need targeted enhancements due to application conditions.

Production Process

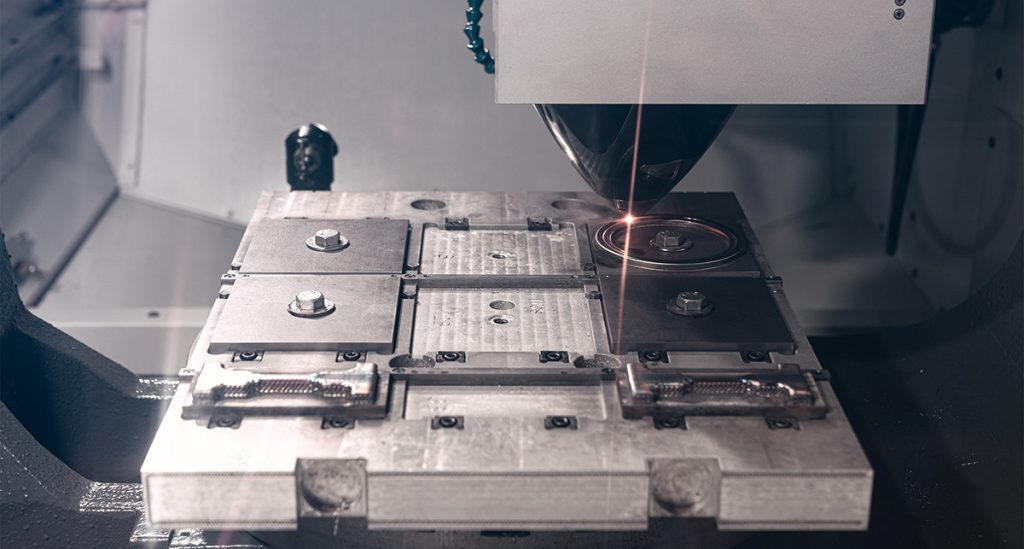

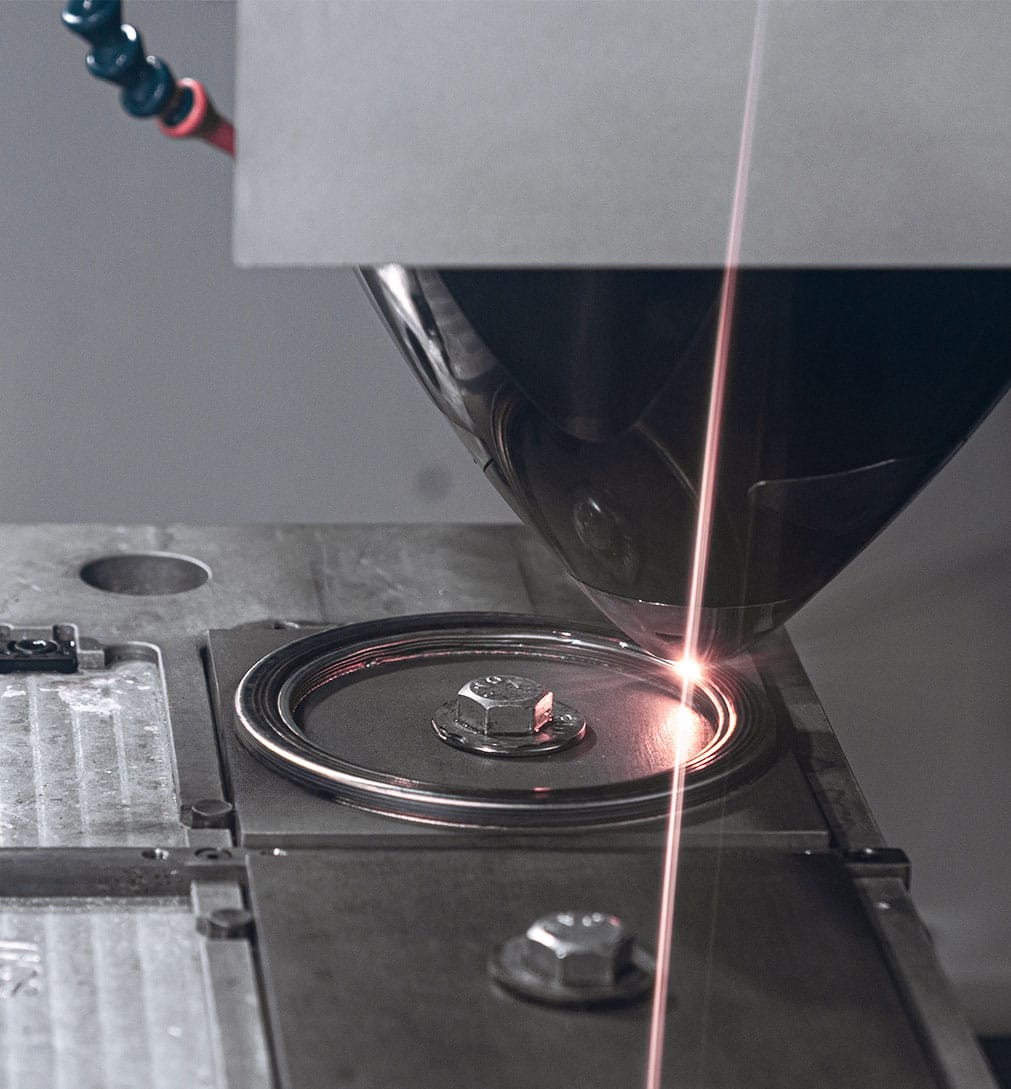

Hybrid Manufacturing with Wire-Laser Metal Deposition (w-LMD)

Hybrid manufacturing is an advanced manufacturing method that combines additive and subtractive within the same system. At Hybrid CNC Parts, we use Haas CNCs with integrated w-LMD Meltio engines. It’s a fast and efficient method for producing precision components.

w-LMD is a direct energy deposition (DED) process that uses lasers to melt metal wire feedstock as it’s being deposited, building up components layer by layer. By using wire feedstock, your material choice options are abundant.

USE CASE

Needle Roller Bearings for Nuclear Systems

These custom engineered and produced bearings are designed for modern nuclear reactor refueling mechanisms, where temperatures can reach 1,000°F. Requirements included the need for bearings of high strength, high hardness, and corrosion resistance.

Project Notes:

- Nickel alloy 718, AWS 5.21 ERCoCr-A (cobalt-based alloy), and H11 were selected for their heat- and corrosion-resistance properties.

- Witness coupons made and tested with every build for process control and material property validation.

- In situ fully-hardened state of H11 achieved without post-processing—reducing lead times, production costs, and increasing performance.

Inner Dimension (in) |

Outer Dimension (in) |

Static Load Capacity (lbf) |

Operational Speeds (RPM) |

Operating Temperature (F) |

|---|---|---|---|---|

2.5 |

3.2 |

10,000 |

200+ |

Up to 1,200 |

Specifications

| Inner Dimension (in) | 2.5 |

| Outer Dimension (in) | 3.2 |

| Static Load Capacity (lbf) | 10,000 |

| Operational Speeds (RPM) | 200+ |

| Operating Temperature (F) | Up to 1,200 |

Benefits of Custom-Made Bearings

Meet exact requirements

Your requirements are unique and all the off-the-shelf bearings are not quite right. Maybe close, but it would mean adjusting the project to make them work. Custom bearings can be made to suit your exact requirements, no matter how niche. Not sure where to start? We can help. Contact us to get started.

Overcome spatial limitations

In some applications that can be little choice for shaft and housing dimensions, like in spacecraft where there isn’t much room to spread out, or geothermal wells where every inch of the drilled borehole is important. Being able to design bearings around other mechanical requirements is a critical consideration.

Supply chain reliability

While some bearings are limited in their production depending on the availability of raw materials, all of our bearings are produced using readily available metal wire feedstock, equating to more reliable lead times.

Improved efficiency

Faster production cycles using hybrid manufacturing due to rapid prototyping, quick design iteration, and lack of extensive tool changes. It also produces less material waste compared to subtractive-only methods.

Industry Applications

Industries across the board utilize custom bearings in order to meet requirements for specialized sizing, operating conditions, and levels of precision.

Examples of various industrial requirements and applications include:

Industry |

Requirements |

Applications |

|---|---|---|

Aerospace |

High temperatures, high precision, unconventional lubrication methods. |

Components in turbine engines, fuel pumps, and control systems. |

Energy |

High temperatures, corrosive and abrasive environments. |

Rotary drills, submersible pumps, valves, compressors, turbines, gear train components. |

Automotive |

High speeds, high temperatures, minimal friction and noise. |

Turbochargers, EV drive trains, wheel hubs. |

Industrial Machinery |

High loads, temperature with abrasion, corrosion, wear resistance. |

Gearboxes, injection and blow molds, material conveyors. |

Medical |

Precision motion control, bio-compatible materials. |

Surgical instruments, infusion pumps. |

Industries across the board utilize custom bearings in order to meet requirements for specialized sizing, operating conditions, and levels of precision.

Examples of various industrial requirements and applications include:

Aerospace

- Requirements: High temperatures, high precision, unconventional lubrication methods.

- Applications: Components in turbine engines, fuel pumps, and control systems.

Energy

- Requirements: High temperatures, corrosive and abrasive environments.

- Applications: Rotary drills, submersible pumps, valves, compressors, turbines, gear train components.

Automotive

- Requirements: High speeds, high temperatures, minimal friction and noise.

- Applications: Turbochargers, EV drive trains, wheel hubs.

Industrial Machinery

- Requirements: High loads, temperature with abrasion, corrosion, wear resistance.

- Applications: Gearboxes, injection and blow molds, material conveyors.

Medical

- Requirements: Precision motion control, bio-compatible materials.

- Applications: Surgical instruments, infusion pumps.

Pricing

Additional information:

In addition to quantity, any/all of the following information is helpful when requesting a quote: approximate bearing size, load capacity, speed, operating environment, bore diameter, housing size, material constraints, operating temperature, industry/application.