Tailored Tools to Fit Your Business

Experience better precision and less downtime with custom and refurbished tooling.

- Custom tool design and manufacture.

- Complex or unique tooling using hybrid manufacturing.

- Tool repair and refurbishment.

- Targeted enhancement for better performance.

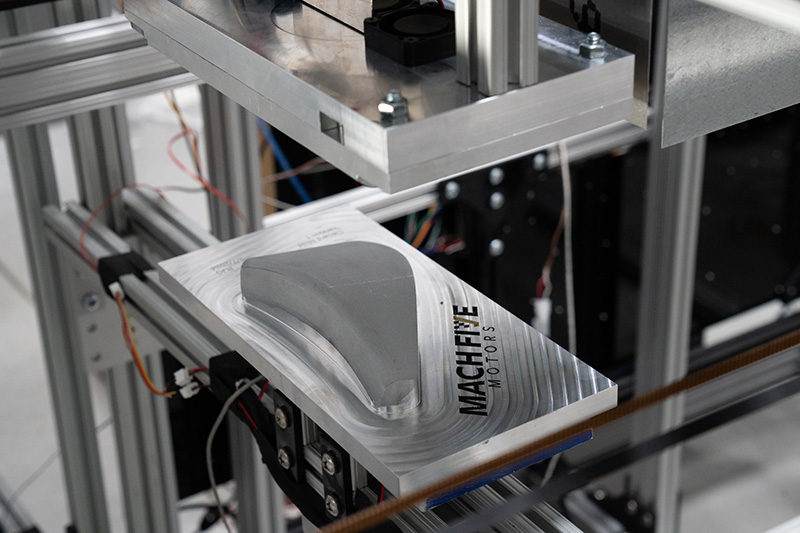

Custom Tool Design & Fabrication

For specialized tools, fixtures, or equipment tailored to the specific needs of your production process or unique product requirements.

Custom tooling optimizes efficiency, improves precision, and accommodates complex geometries or materials that are otherwise difficult or impossible to obtain with standard tools.

Reduce downtime by using tooling that fits perfectly into your existing workflows.

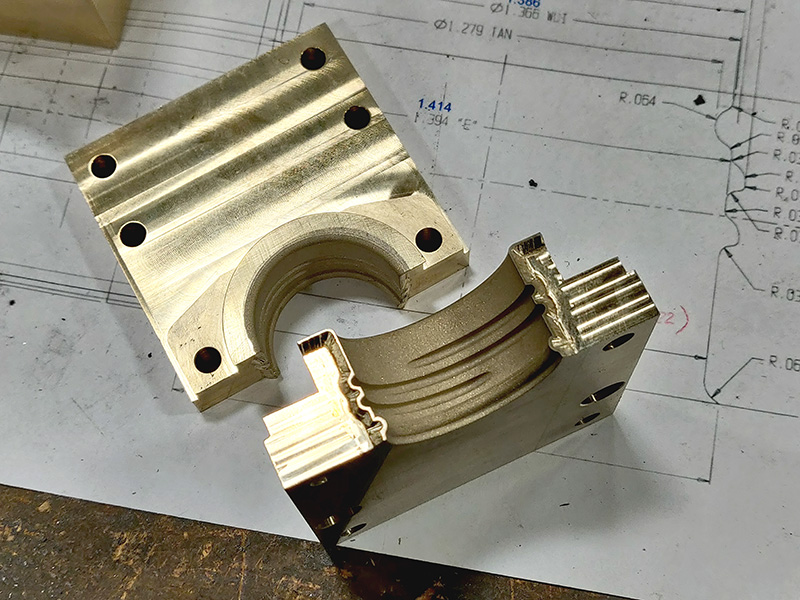

Tool Repair & Refurbishment

Tool repair or refurbishment with hybrid manufacturing is an efficient means to extend component lifecycles while reducing replacement costs. Precisely rebuild or restore damaged or worn-out sections of a tool, or add material directly to worn surfaces and finish accurately to a high standard.

Refurbishment not only improves the performance of tools, but also enhances sustainability by minimizing waste, increasing efficiency, and improving the reliability of manufacturing operations.

Examples of tooling include extrusion dies, blow mold tools, and injection molding.

Tool Enhancement

Our wire-laser hybrid manufacturing technology enables precise deposition of metal material, allowing for the creation or reinforcement of complex tool geometries and wear-resistant surfaces.

Enhanced tools can be more efficient, accurate, and durable, leading to more consistent parts and reduced maintenance.

Why Custom Tooling?

Efficiency

Tailored tools fit specific production needs, speeding up processes and reducing downtime.

Accuracy

Custom tooling ensures better precision, resulting in products with tighter tolerances.

Flexibility

Ideal for complex or unique parts not accommodated by standard tools.