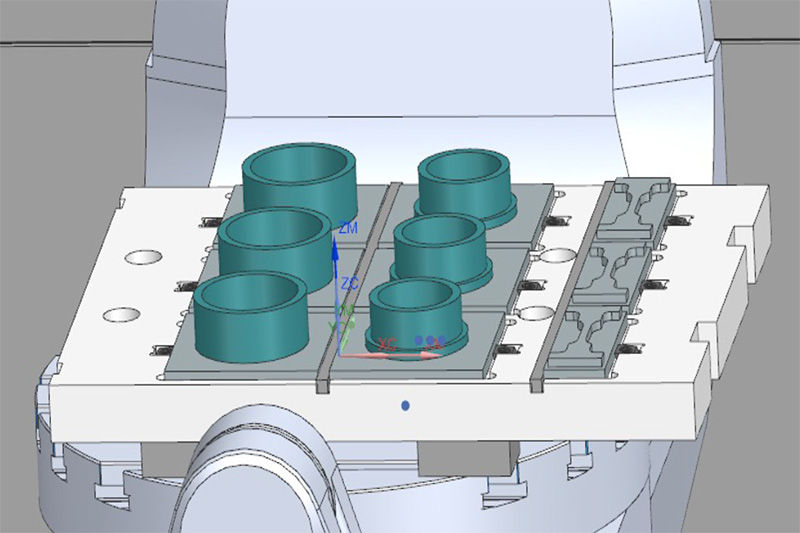

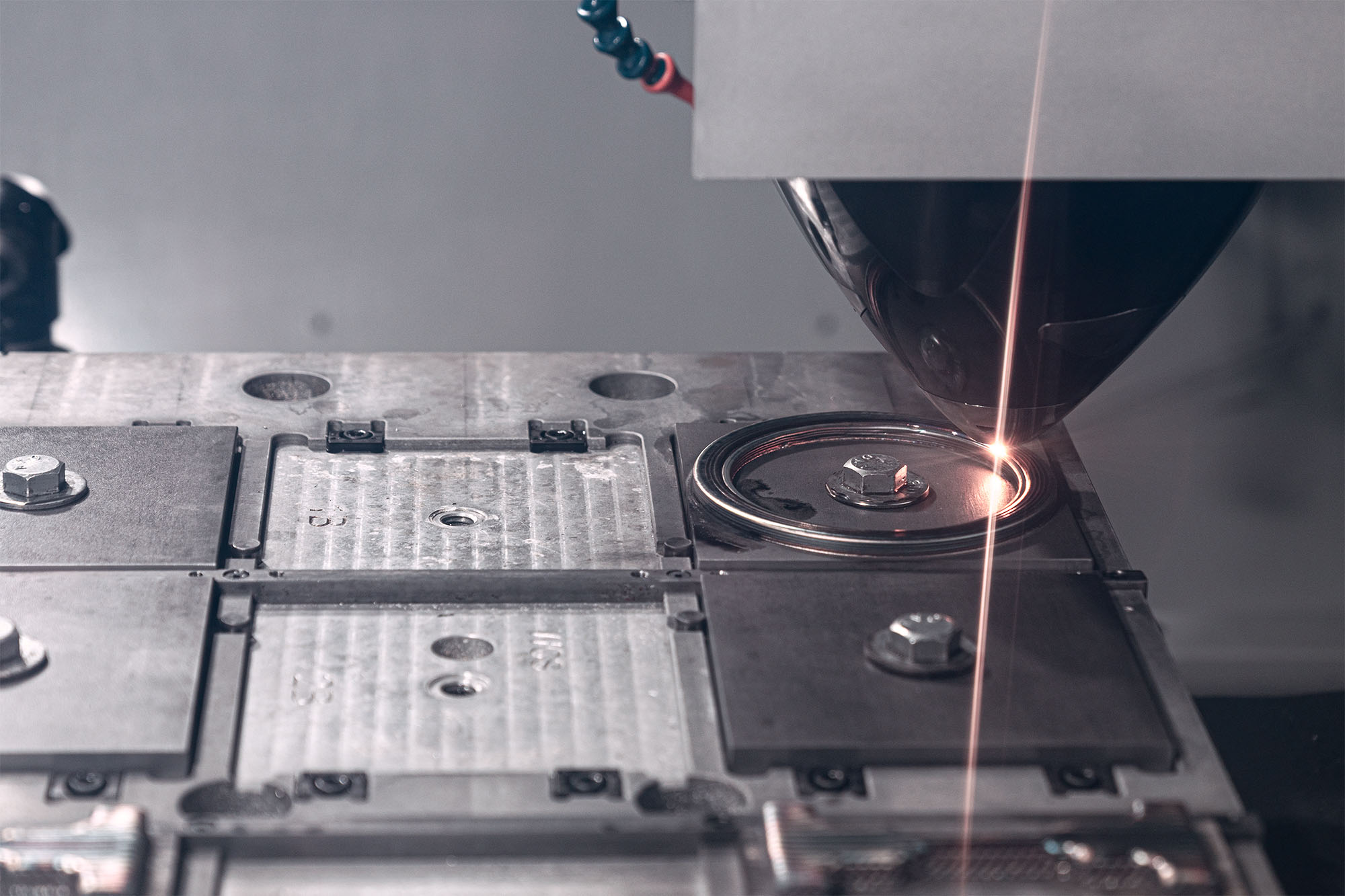

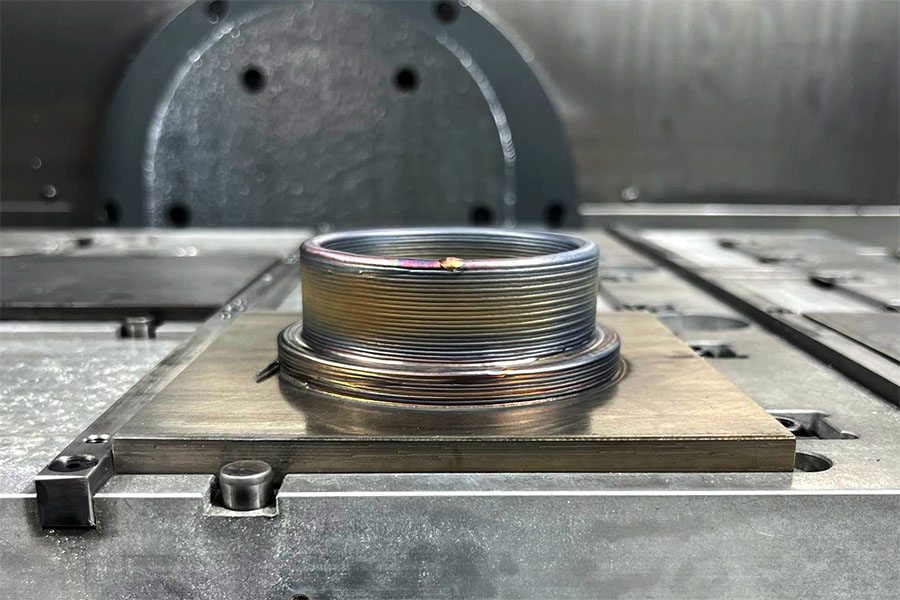

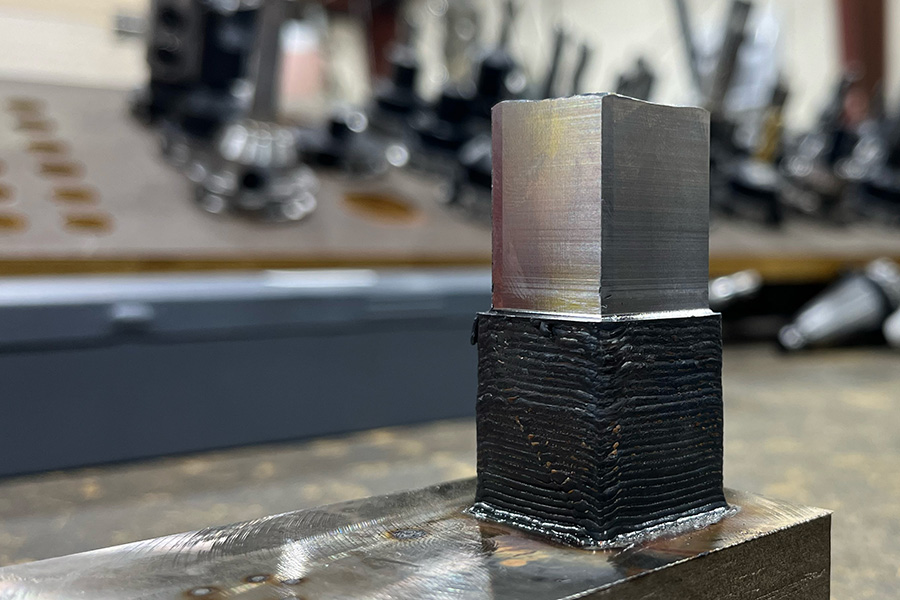

When it comes to critical parts—whether it’s bearings for high-temperature corrosive environments, mold tools, or performance automotive parts—getting it right the first time is non-negotiable.

Often you know exactly what you need and what materials meet the application requirements. But sometimes the best material isn’t clear, or you might be interested in a higher-performing option.

From tool steels to superalloys, we have the expertise to guide you toward the best material for your application and the know-how to machine it.

- Specialists in hard to machine, heat-resistant materials.

- Expertise in functionally-graded, multi-alloy components.

Materials & Properties

The following table demonstrates materials we can accommodate and relative property applicability.

Materials & Properties

The following table demonstrates materials we can accommodate and relative property applicability.

Material |

Lightness |

Heat Resistance |

Corrosion Resistance |

Hardness / Wear Resistance |

ISO Group |

Example Brand Names & Grades |

|---|---|---|---|---|---|---|

Nickel |

– |

ISO S Heat-Resistant Superalloys |

Inconel®, Hastelloy®, Monel®, Techalloy® / Nickel 625, 718, X-750, C-276 |

|||

Cobalt |

– |

ISO S Heat-Resistant Superalloys |

Stellite®, Haynes®, Ultimet®, Polystel® / Cobalt 6, 20 |

|||

Titanium |

– |

ISO S Heat-Resistant Superalloys |

Grade 2, Grade 5 |

|||

Stainless Steel |

– |

ISO M Stainless Steel |

304, 316 H, 316 L, 440C, 17-4PH |

|||

Carbon Steel |

– |

– |

– |

ISO P Steel |

1018, 1045, A36 |

|

Tool Steel |

– |

ISO H Hardened Materials |

H11, H13, M2, M50, T1, D2 |

|||

Aluminum |

– |

ISO N Non-Ferrous Metals |

6061, 7075 |

Materials & Properties

The following list demonstrates materials we can accommodate and relative property applicability.

Nickel

ISO S: Heat-Resistant Superalloys

Example Brand Names & Grades:

Inconel®, Hastelloy®, Monel®, Techalloy®

Nickel 625, 718, X-750, C-276

Lightness: –

Heat Resistance:

Corrosion Resistance:

Hardness/Wear Resistance:

Cobalt

ISO S: Heat-Resistant Superalloys

Example Brand Names & Grades:

Stellite®, Haynes®, Ultimet®, Polystel®

Cobalt 6, 20

Lightness: –

Heat Resistance:

Corrosion Resistance:

Hardness/Wear Resistance:

Titanium

ISO S: Heat-Resistant Superalloys

Example Grades:

Grade 2, Grade 5

Lightness:

Heat Resistance:

Corrosion Resistance:

Hardness/Wear Resistance: –

Stainless Steel

ISO M: Stainless Steel

Example Grades:

304, 316 L, 316 H, 440C, 17-4PH

Lightness: –

Heat Resistance:

Corrosion Resistance:

Hardness/Wear Resistance:

Carbon Steel

ISO P: Steel

Example Grades:

1018, 1045, A36

Lightness: –

Heat Resistance: –

Corrosion Resistance: –

Hardness/Wear Resistance:

Tool Steel

ISO H: Hardened Materials

Example Grades:

H11, H13, M2, M50, T1, D2

Lightness: –

Heat Resistance:

Corrosion Resistance:

Hardness/Wear Resistance:

Aluminum

ISO N: Non-Ferrous Metals

Example Grades:

6061, 7075

Lightness:

Heat Resistance: –

Corrosion Resistance:

Hardness/Wear Resistance:

ISO Material Groups

ISO Material Groups classify different metal families by their machinability to help categorize the techniques and tooling required to work with different alloys.

Understanding these groups helps machinists ensure high precision and longer tool life, and sometimes material knowledge can even help engineer a better product through judicious material selection.