Vertically-Integrated Manufacturing

Our vertically-integrated engineering services accommodate parts to print as well as flexible, bespoke manufacturing solutions for those industries that often require unique components in low volumes.

- Your one-stop shop for manufacturing services, from design through to testing.

- Advanced methods, like hybrid manufacturing, support innovative solutions to complex design challenges.

- Specializing in heat-resistant alloys that are hard to machine with conventional manufacturing.

- 100% USA-based manufacturing in Worcester, MA.

- Safeguarding sensitive data through compliance to NIST, DFARS, and CMMC standards.

Capabilities

Download our 1-page Capabilities PDF for a quick reference to our services.

Capabilities

Download our 1-page Capabilities PDF for a quick reference to our services.

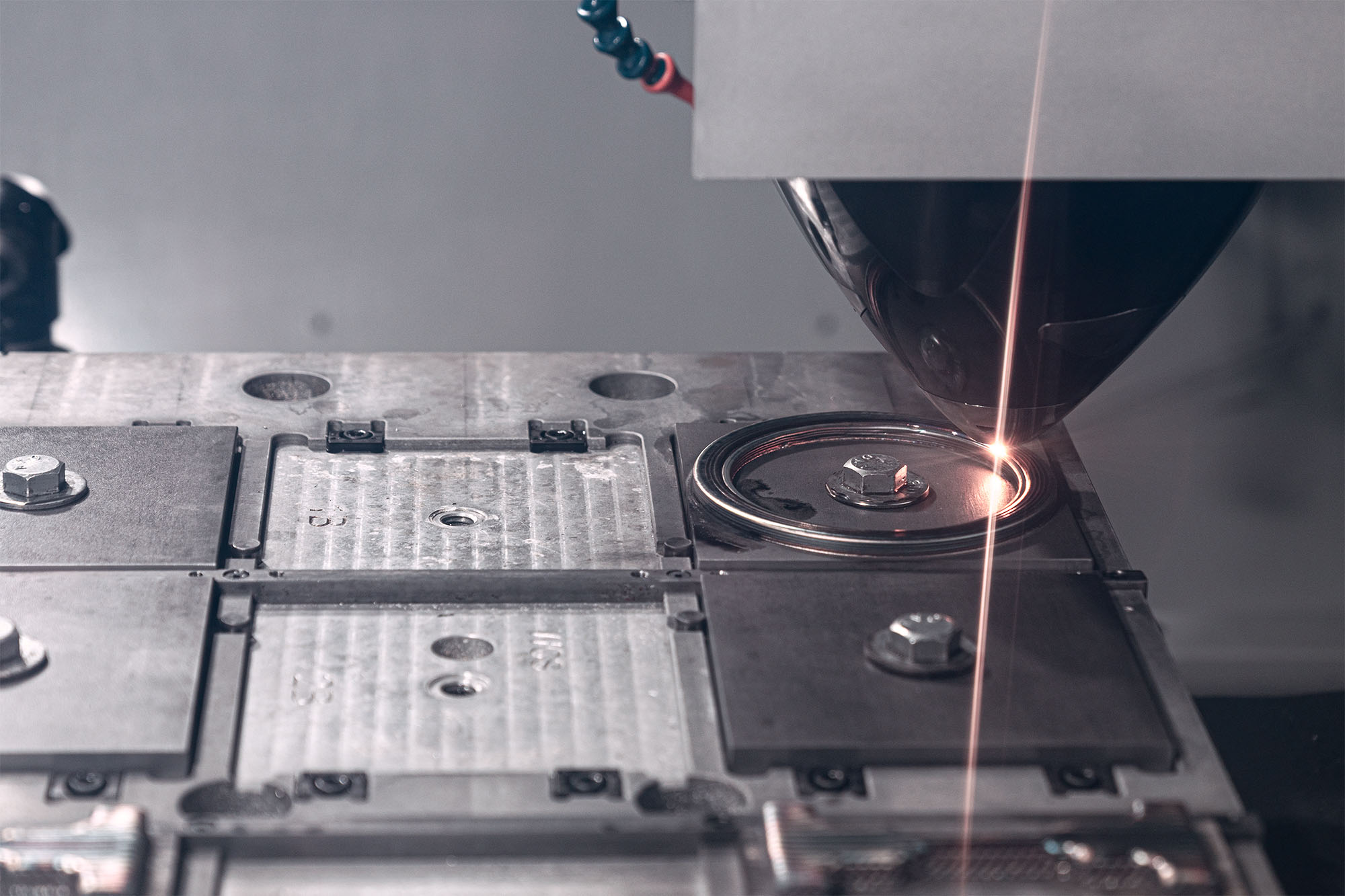

Production

Custom and turnkey services, focusing on advanced manufacturing methods. Providing flexible, low-volume production for niche markets and specialized components.

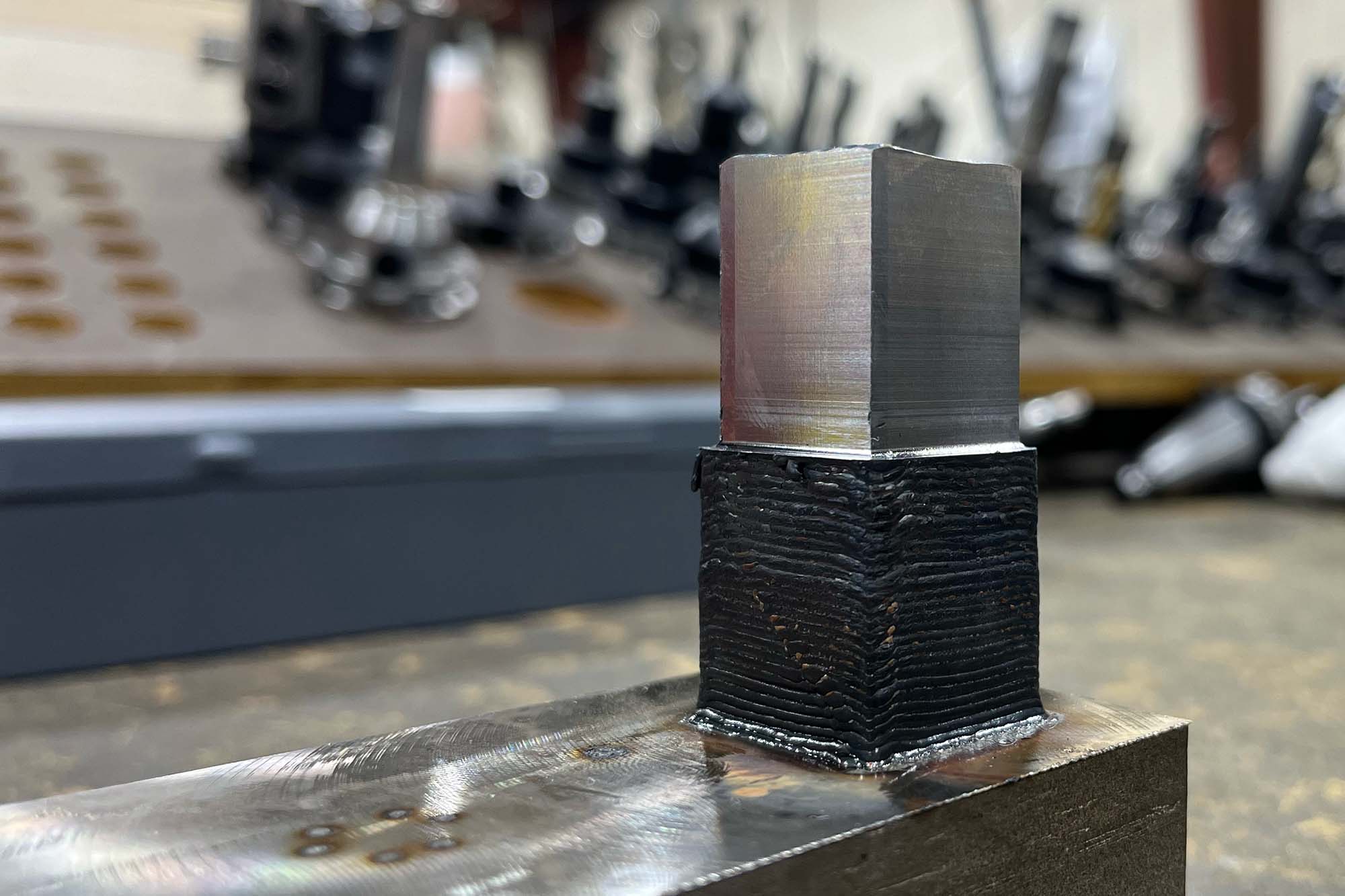

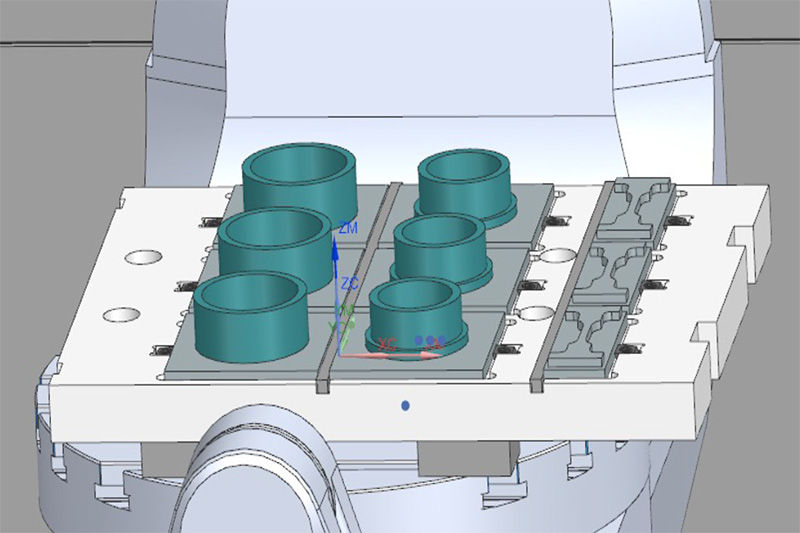

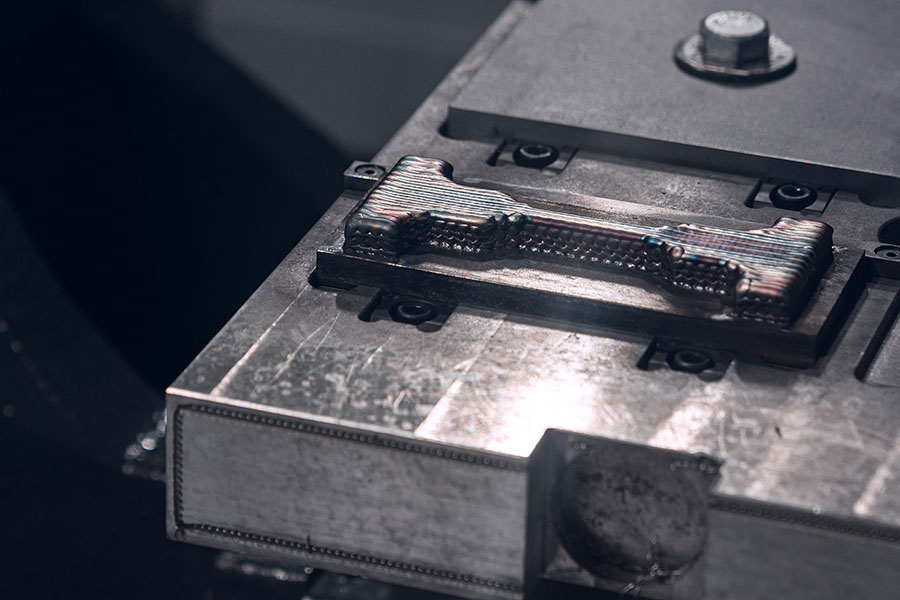

Hybrid Manufacturing

Advanced manufacturing combining additive and subtractive methods. Create custom component with unique features, complex geometries, and multiple alloys.

Design & Engineering

Components designed to your requirements. Expertise in complex geometries, integrated functionality, and multi-alloy components. Reverse engineering for those legacy parts that you no longer have the specs for.

Rapid Prototyping

Quickly test and iterate designs for accelerated production cycles.

Inspection & Testing

In-house testing and verification provides fast and efficient analysis of manufactured components.

Molds & Tooling

Design and manufacture of custom tooling. Repair, refurbishment, and targeted enhancement.