Product Quality and Compliance

Inspection and testing solutions improve product quality, reduce defects, and ensure compliance with industry standards.

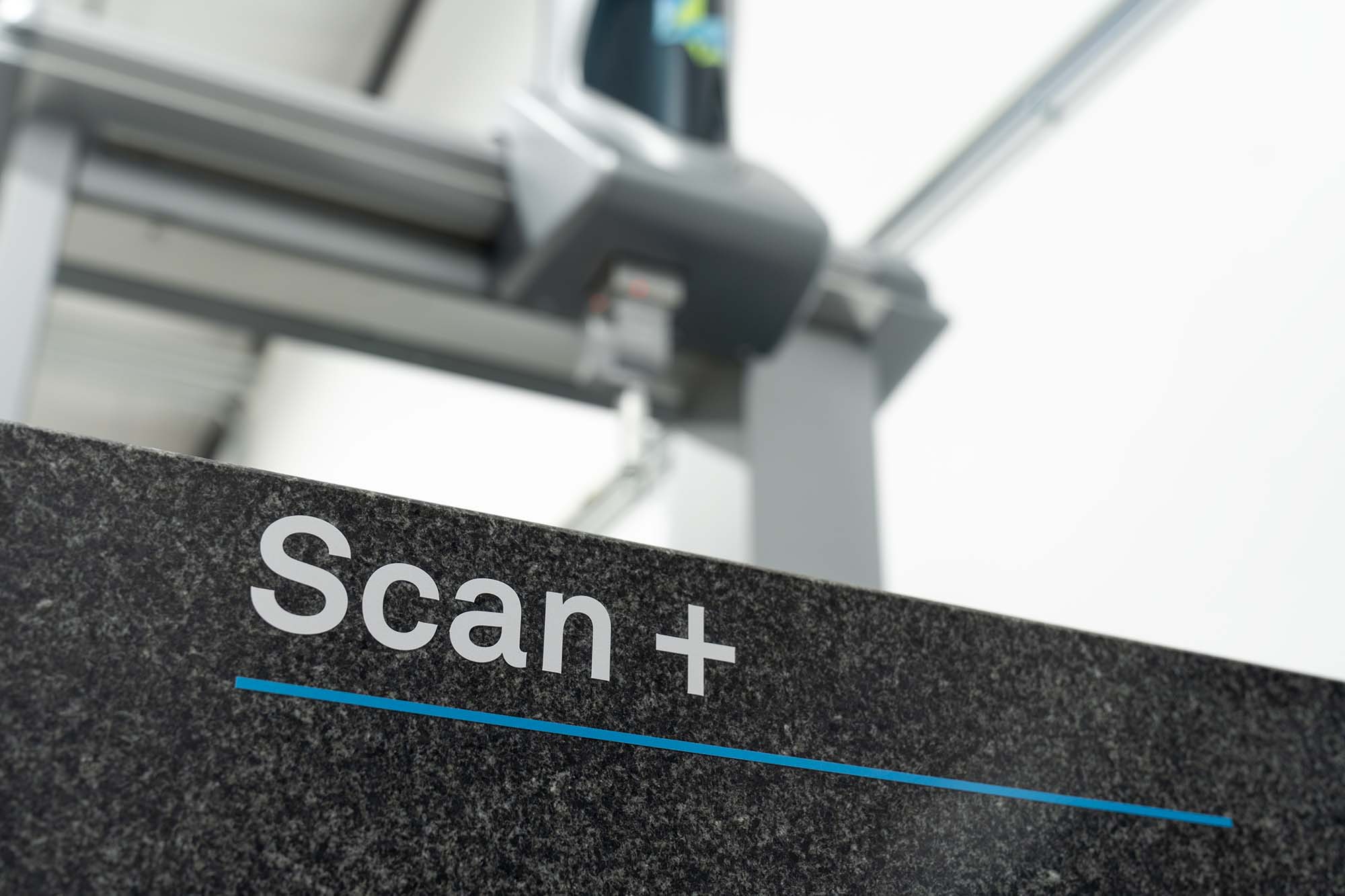

- Full-part inspection with Hexagon GLOBAL Scan+ CMM.

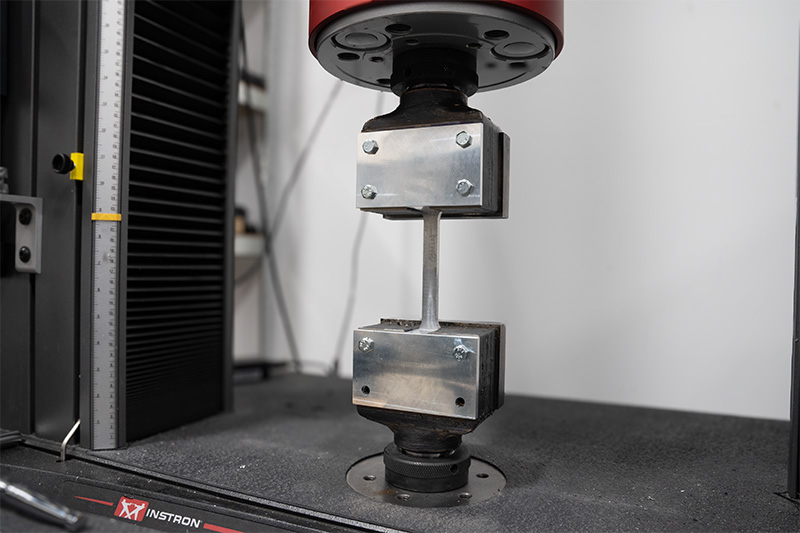

- Mechanical testing with Instron Universal Mechanical Tester.

Why Inspect and Test?

Inspection and testing are critical processes that ensure product quality and compliance with industry standards. Inspection involves examining products at various production stages to identify defects or deviations. Testing evaluates the performance, durability, and safety of products under different conditions. Together, these processes help detect issues early, reduce waste, and ensure that final products meet customer expectations and regulatory requirements.

Inspection

For full-part inspection, verification, and quality control, our Hexagon GLOBAL Scan+ Coordinate-Measuring Machine provides high-precision measurements to ensure components meet specifications and tolerance requirements.

Additional inspection capabilities:

- ThorLabs Optical Microscope: Custom assembly bright field optical microscopy setup with 12-48x magnification at 60 fps for full-color characterization and quantification down to the 1 μm scale.

- Infrared Thermal Camera: Contact-free thermal measurements from -14 ℉ to 752 ℉.

- MS-Polariscope™: Contact-free optical metrology system for non-destructive quality evaluation of selected polymer prototypes.

More information

Testing

In-house testing provides fast and efficient analysis of manufactured components. Characterizing of material properties under compression, extension, oscillatory loading, 3-point bending, and peel testing using our Instron Universal Mechanical Tester. ASTM standards (convertible to ISO) and custom testing configurations available.