Cutting-Edge Manufacturing Methods

Manufacturing solutions for specialized and custom components, using the latest in advanced manufacturing methods.

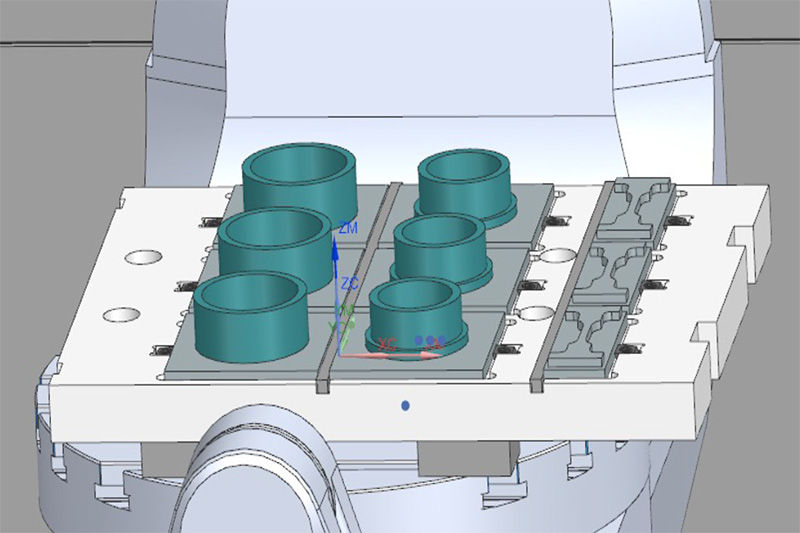

- Advanced manufacturing and modern 5- and 3-axis milling.

- Flexible, low-volume production for niche markets and specialty components.

Custom and Turnkey Manufacturing

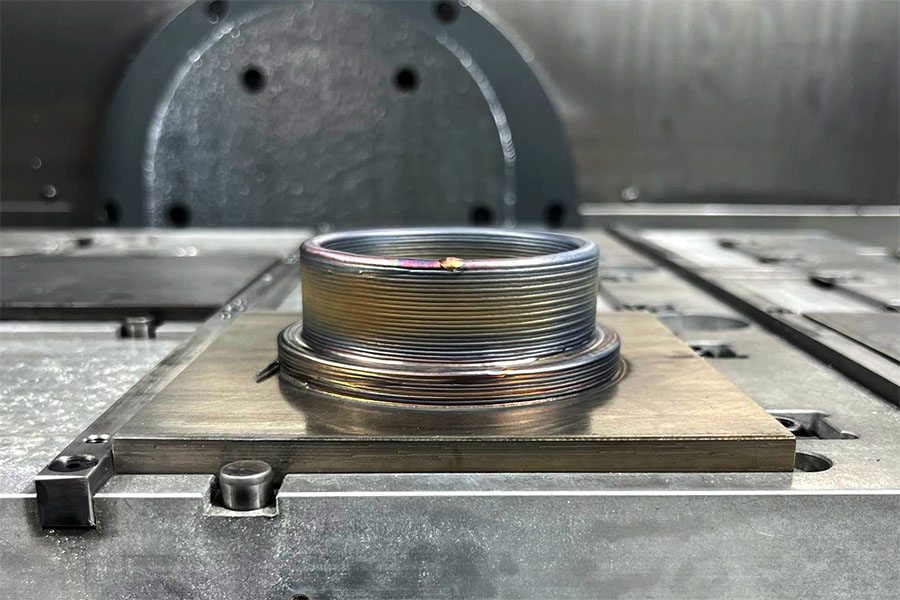

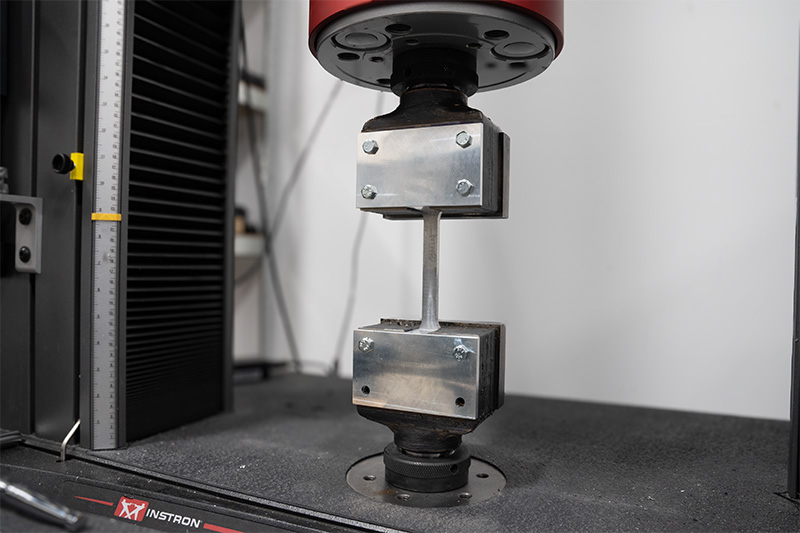

Our highly skilled and diverse team works closely with our customers to provide close tolerance parts and can work from existing specifications or create new designs. Hybrid and subtractive-only manufacturing is carried out using the latest in wire-laser metal 3D printing and CNC systems.

We provide low-volume, specialty manufacturing with attention to quality, precision, and unique requirements. In doing so, we provide our customers an uncommon degree of flexibility.

Our manufacturing is:

- 100% U.S.A-based in Worcester, MA.

- Is compliant with NIST SP 800-171 / DFARS 252.204-7012 / CMMC 2.0 Level 2.

- Carried out at our parent company’s facilities that are ISO 9001 and AS9100 certified.

Hybrid Manufacturing

Level up with innovative wire-laser 3D hybrid manufacturing

As our name suggests, Hybrid CNC Parts places a strong focus on hybrid manufacturing solutions. Hybrid manufacturing is an advanced manufacturing method that incorporates both additive and subtractive processes within a single system. It allows for complex geometries, consolidated functions, targeted repair, and enhanced mechanical properties, and is ideal for high-performance parts and precision engineering applications.

Hybrid CNC Parts is one of only a handful of commercial manufacturers to provide wire-laser metal deposition hybrid capabilities to their customers.

Material Selection

We are able to offer our customers a range of materials, from nickel-based superalloys like Inconel® and Stellite® to stainless steels and non-ferrous metals.

Every component is assessed for the most appropriate material(s) based on requirements. If you’re unsure what material is best suited to your application, we are happy to discuss potential solutions.